Book & Catalogue Binding

There are many different binding methods for books, catalogues and brochures. The following gives a brief overview of the characteristics of the main ones.

Our print management service includes complete catalogue and brochure production from the initial design right through to printing, binding and distribution.

-

Saddle stitched

Has the appearance of 2 staples on the spine.

-

Loop wire stitched

Very similar to saddle stitching but 2, or 4, loops are created with the wire so that you can file the document into a 2 or 4-ring binder.

-

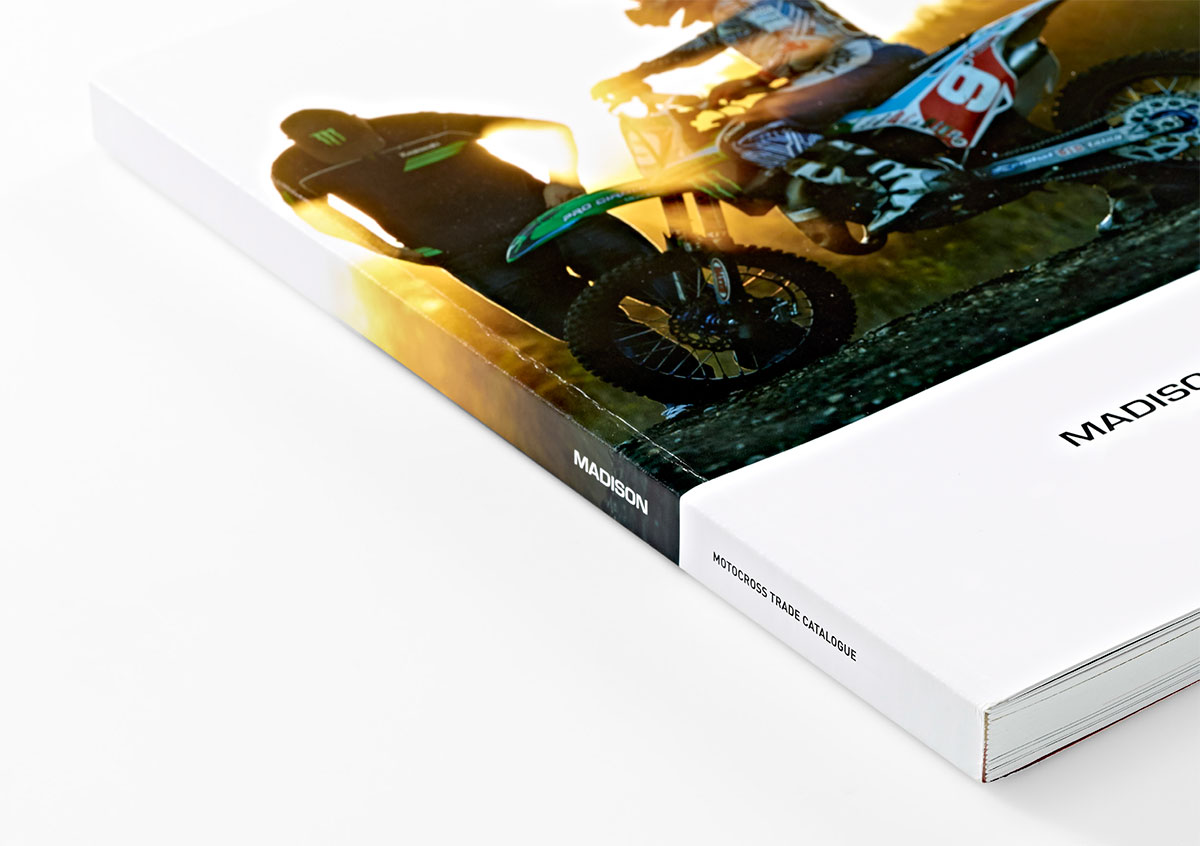

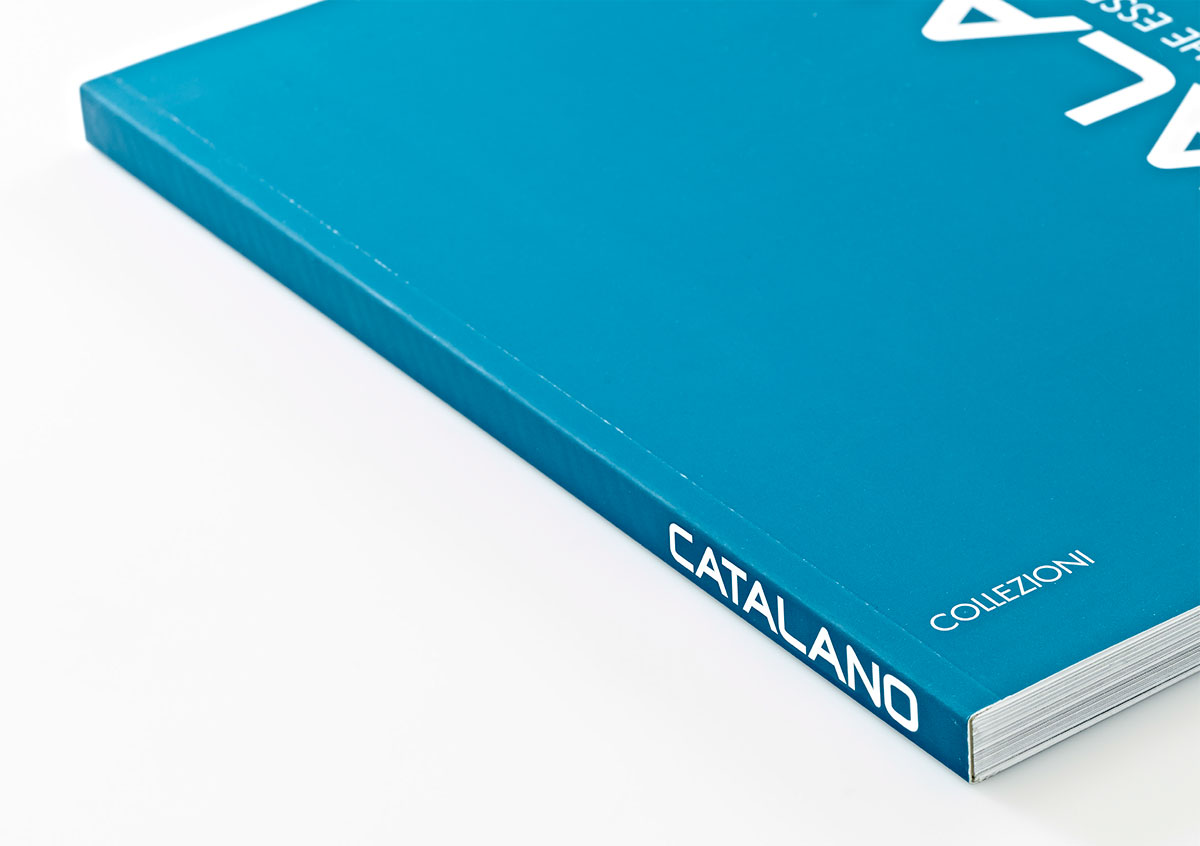

Perfect bound

Pre-folded pages have their spines trimmed off then the sections are collated and glued to the wrap-around cover which gives a ‘square’ spine effect. Depending upon the number of pages, and the paper/board types being used, perfect binding cannot be used under a certain pagination.

-

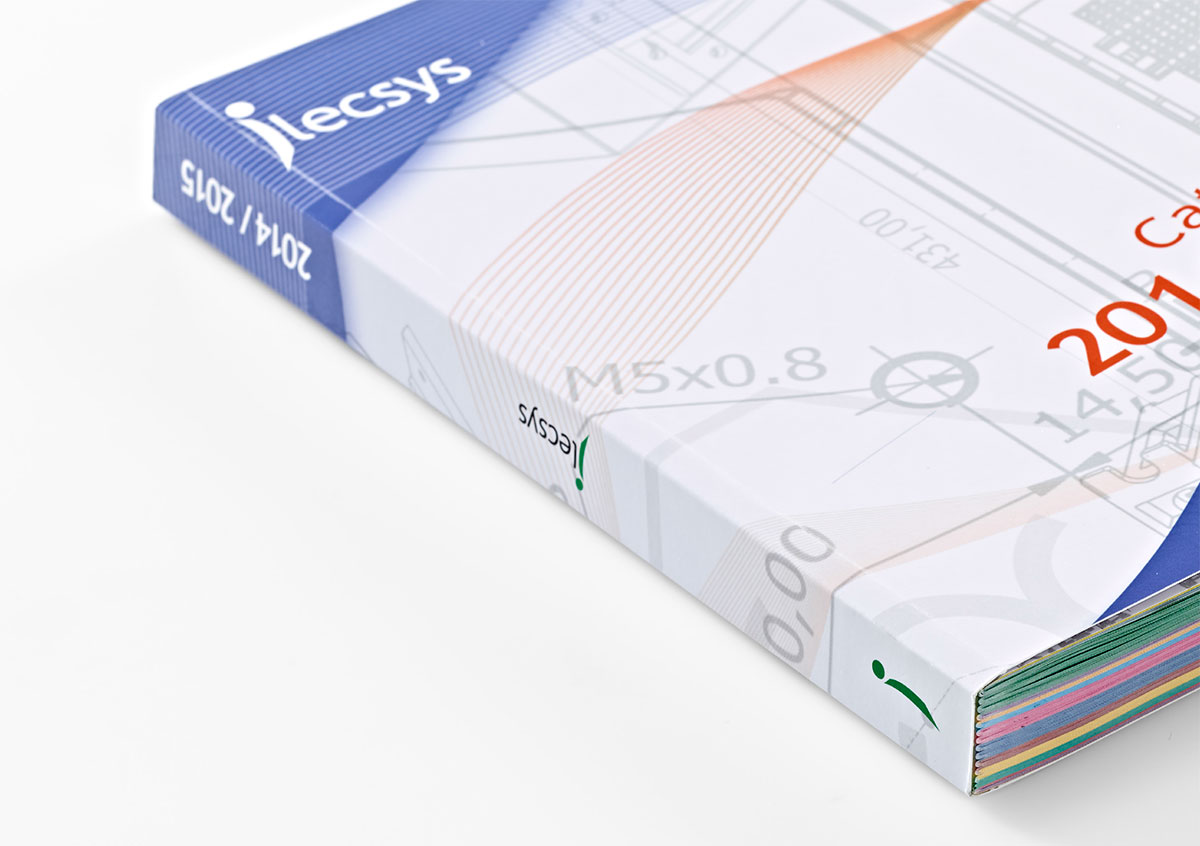

PUR bound

Very similar to perfect binding but the adhesive is PUR (polyurethane reactive). This gives a stronger, more flexible adhesion and can allow a publication to ‘lay flat’ to a greater extent.

-

Thread sewn

From the outside can look to be the same as Perfect or PUR binding but the sections are stitched together with thread before being bonded to the cover.

-

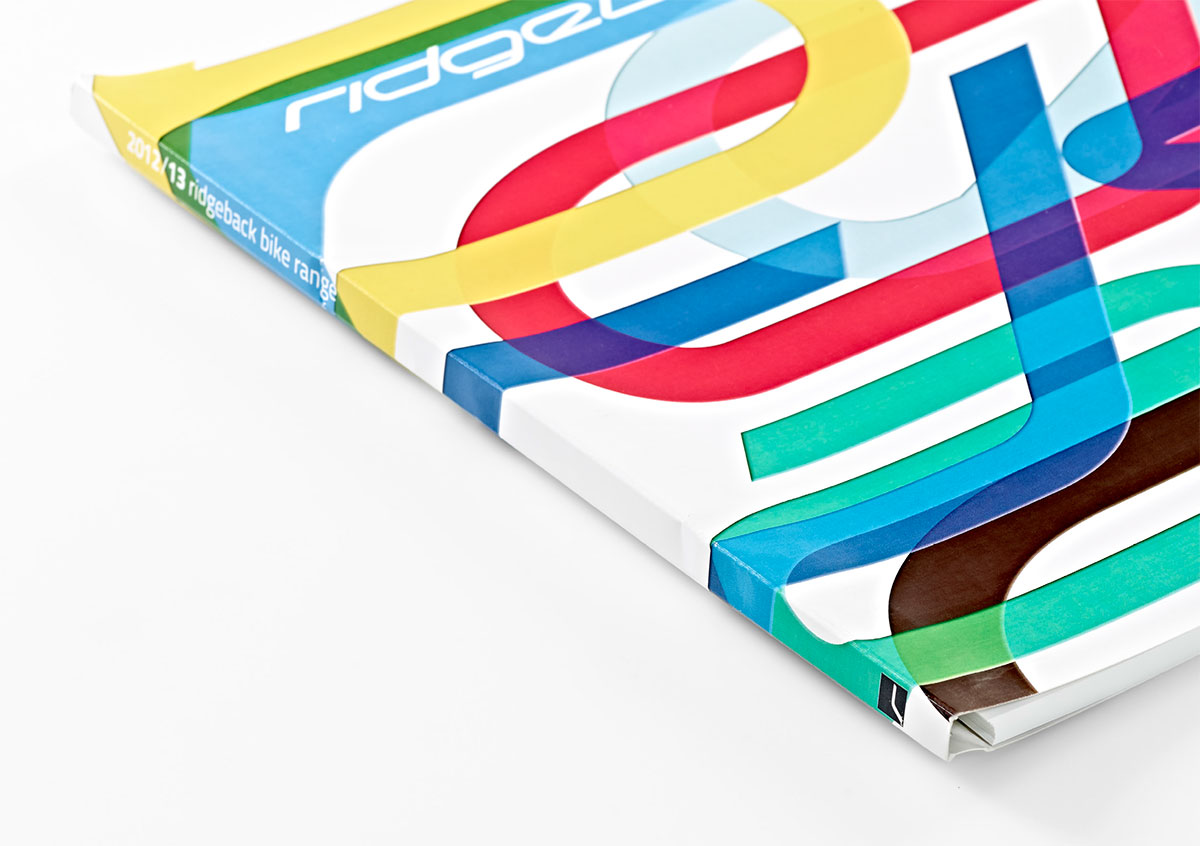

Full-Canadian and Half-Canadian bound

Full-Canadian and Half-Canadian bound jobs are wire-o bound but with the covers showing the wire on both the front and back (Full) or back only (Half). The benefits are that a spine can be printed (as an integral part of the cover) and the book still be opened flat.

-

File Hole Drilled

Drilling 2 or 4 holes near the spine to facilitate insertion into a ring binder Sheets of paper, either single ply or multi-ply NCR sets, are collated with a board base and glued at the top to form pads.

-

Plastic comb bound

A continuous ‘spiral’ of wire is threaded through pre-punched holes on the edge to be bound.

-

Case bound

Case bound books are made of greyboard and covered with printed paper, bookcloth, leathercloth or real leather and you can add foil blocking, head and tailbands, coloured end papers, printed book jackets, or printed paper covers which can be gloss or matt laminated. The book sections are sewn together then attached to the inside of a case with endpapers which are tipped on to the bookblock and then glued into the case.

-

Wire-o bound

A nylon or metal ‘thread’ is inserted into pre-punched sheets which is then crimped to provide strength. A neat method of binding and useful if the document must open flat.

-

Stab stitched

Sheets of paper, either single ply or multi-ply NCR sets, are collated with a board base and stitched with 2 wires at the top or side to form books. A strong tape is often used to cover the stiches.

-

Spiral bound

A continuous ‘spiral’ of wire is threaded through pre-punched holes on the edge to be bound.